In the paper industry, wet waste management is a constant issue. Production operations generate large quantities of waste in paper sludge, which must be handled appropriately to maintain productivity while complying with strict environmental standards. Disposing of this sludge represents a significant cost and a major source of pollution linked to transport.

A fast, efficient tool for drying paper sludge

The Mini Green Power dryer reduces the moisture content of sludge from 70% to just 15%. This means that a material previously a wet mass, difficult to manage, is transformed into a dry substance that is easy to store and transport. This superior performance translates into faster waste treatment, more efficient energy use and a significant reduction in environmental impact.

Despite the impressive drying performance, Mini Green Power has designed this technology compactly. Even operations with limited space for additional equipment can accommodate a Mini Green Power dryer. In addition, the dryer is designed to be easily integrated into existing production lines, minimising the need to reorganise operations or purchase additional equipment. This dryer is one of the most compact on the market.

Cost-effective and adaptable to the changing needs of paper mills

The dryer's ability to reduce sludge moisture and, therefore, weight also means substantial savings. The Mini Green Power dryer considerably reduces these costs by drying the sludge. The return on investment for these dryers is around three years, depending on the size of their operation and the volume of waste treated.

Mini Green Power has designed its dryers to be modular and capable of adapting to different waste volumes. So whether you run a small paper mill of a few thousand tonnes or a large production plant, Mini Green Power dryers can meet your needs. Drying lines can be added in parallel to increase drying capacity as your production increases.

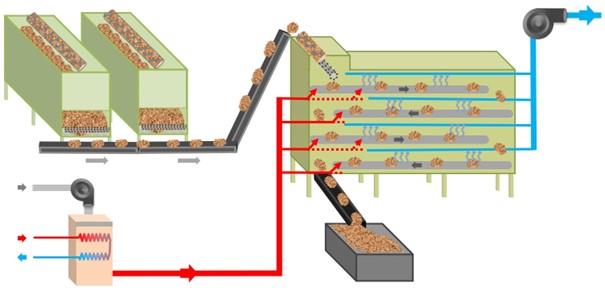

How the dryer works

A tiered system with perforated moving floors makes the drying process possible. Hot air is blown through these perforations, ensuring uniform sludge drying. The result is an optimised drying process offering maximum efficiency and minimum energy consumption.

At the heart of the Mini Green Power dryer is an exchanger that produces hot air from a hot water loop. This hot air passes through the sludge to be dried, expelling the moisture by evaporation. The result is a dry sludge that is easy to handle and ready for the next stage in the production process or disposal.

Optimising wet waste management has never been so accessible! This dryer enables paper mills and all industries faced with the production of wet waste not only to reduce their costs and improve their efficiency but also to take a major step towards environmental sustainability. With its unique drying performance, compact and adaptable design, and ability to deliver a rapid return on investment, the Mini Green Power dryer is a valuable asset to any modern paper mill.

👉 You have a dryer project ? Contact us !

👉 You want to link this dryer to a power plant producing low-carbon energy ? Discover the Mini Green Power plants

3 September 2024